Bay City Flower Company to close

The news came to me second-hand through industry colleagues, and also from a local newspaper: Bay City Flower Company of Half Moon Bay, California, is closing after 110 years in business. Bay City’s Hana Bay Flowers brand has been a staple in grocery store floral departments across America for generations.

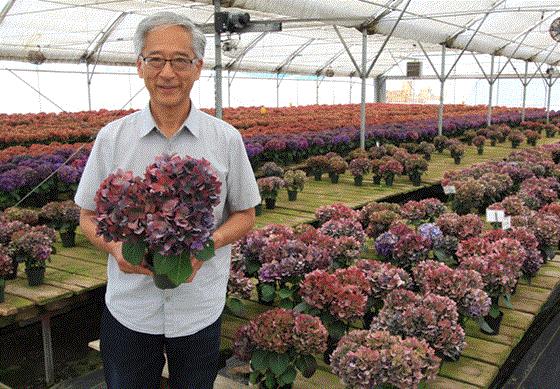

Fourth generation Harrison Higaki in 2013.

Fourth generation Harrison Higaki in 2013.

A reader shared the official statement from the company, signed by fourth-generation owner Harrison Higaki, that went out to customers. His first two paragraphs read:

“After four generations and 110 glorious years in floriculture, we at Bay City Flower Company have decided that the time has come for us to stop selling our flowers. The last day shipping our finished products will be 11/10/19.

“While there are many reasons for this decision, the essential one is that it has become increasingly difficult to compete nationally while operating in the costliest place in the nation to run a flower farm.”

Harrison continued that they are making arrangements with other “reputable growers” to help customers find future plants, especially for the Thanksgiving and Christmas holidays. He concluded with this:

“While we are sad to share this news with you, at the same time, we celebrate the multitude of accomplishments we, in partnership with you have achieved over these many years. We truly could not have done it without you.

“Our hearts are filled with joy and gratitude for the many individuals and companies that have journeyed together with us over these many years. We are particularly grateful to those that have been with us over multiple generations.

“We wish to extend to you a sincere & heartfelt ‘Thank you!’”

Sad news!

I’ve always had the utmost respect for Harrison as a grower, a businessman and an advocate for the industry. His family has a long history with GrowerTalks; I know Vic Ball was friends with Harrison’s dad, Harry. Harry’s father, Nobuo, who founded Higaki Nursery in 1910, was interred in North Dakota during World War II. The family was forced to leave the business, but a fellow grower leased it and kept it going until they were able to return.

I reached out to the company for a comment on the decision. Lisa Higaki, Harrison’s daughter, replied. I first asked her if they had given any thought to moving the business to a less-expensive state. “We did not consider that possibility,” was her reply.

I then asked what will become of the facilities? Will you try to sell the business? Or sell the land to developers? Replied Lisa, “Our focus right now is on winding down the operations and closing. While we have had discussions on possible uses for the property, no decision has been made and we are focusing on the November 10th closing for finished blooming and 2/29/20 for growing on dormant hydrangeas. Currently, we are busy fulfilling our finished sales commitments with retailers for Christmas and through October 2020 by selling our pre-finished flowering plants or dormant hydrangeas for finishing in 2020.”

In other words, the Higaki family is still all about taking care of the customer.

As sorry as I am to see a 110-year-old family business close its doors, time marches on, and the vacuum they leave in the potted plant world may be filled by a young, enthusiastic grower looking to make his or her mark on the industry.

Doing business in California

My last visit to Bay City (when I shot that photo of Harrison with his beautiful antique hydrangeas) was back in 2013, just a year or so after Bay City’s neighbor, Nurserymen’s Exchange, was taken over by Rocket Farms, so potted plant nurseries were already facing tough times. Harrison gave me the full tour, focusing specifically on hydrangeas, which were especially hot at the time. They were doing some beautiful antique shades that sold at higher prices than regular (but also needed much longer on the bench). I don’t recall if he brought up the challenges of operating in high-priced California.

Back then, California’s minimum wage was $8 per hour. Today, it’s $12, increasing to $13 in 2020 and $15 by 2022. Of course, it’s a rare business these days that only pays minimum; it usually requires several dollars more per hour just to compete with fast food jobs. And that’s just wages; I suspect other labor costs also are a burden. Meanwhile, have you checked potted plant prices at your local grocery store? The same as they were 10 or more years ago, I suspect.

A local newspaper report says that 60 people have been laid off at Bay City already, and as many as 190 more will be losing their jobs—perhaps an unintended consequence of California’s minimum wage policy.

For those of you who do business in California—and plan on continuing to do so—feel free to weigh in with the realities on the ground, at beytes@growertalks.com. Every state has its pros and cons, and one business's challenge may be another's opportunity.

Heimos adds hemp

Yet another ornamental grower has found a side business in the world of hemp. N.G. Heimos of Millstadt, Illinois, down by St. Louis, has signed on with a Denver breeding company called Trilogene Seeds to produce hemp seed—specifically, “feminized” hemp seed, which Trilogene says is desirable, as it ensures the crop will be 99% female plants (more on this in a bit).

“With the growing demand from the agricultural and health and wellness industries, the need to increase the production of feminized hemp seeds is critical,” said Matt Haddad, Trilogene’s founder and CEO. “We have been committed to developing our craft hemp strains for over four years to help stabilize unique varieties for farmers all over the world. Being able to grow our seeds in Heimos’ controlled environment will ensure the purity of our feminized genetics and our ability to produce and provide vigorous varieties that will yield massive CBD and other minor cannabinoids output for non-psycho-active cannabinoid farmers.”

In 2019, Trilogene planted 1.3 million feminized hemp seeds all over the United States, from Colorado to Delaware to Hawaii. This new alliance, Matt said, will up the production to over 100 million seeds by June of 2020.

Bernie Heimos, president of the family business, explained in a statement, “This partnership hits the core of our business by expanding production into today’s relevant crops. Although we have no plans to exit the horticulture field, we feel this decision makes sense for us in our expansion plans.”

To learn a bit more than what the press release offered, I emailed Bernie the following questions:

Acres Online: Why add hemp seed to your flower business?

Bernie: Since the Farm Bill passed and hemp has become legal to produce, we have been doing seed starts for local farmers. We signed the deal with Trilogene because they have some very good genetics and we feel we can produce seed at a reasonable cost.

AO: What do you anticipate the benefits being for Heimos, short and long term?

Bernie: We see this as another branch of our business. We are now working toward adding greenhouses to do this production in, and it needs to be a stand-alone profit center.

AO: You’re going to be producing seed? Can you explain a bit about how that works?

Bernie: Seed is the product as well as seed and clone starts for the farmers in our area. The process is proprietary to Trilogene, so I will not discuss that.

AO: How much of your space will hemp occupy?

Bernie: We are currently using 1 acre of our space, but plan to expand to 4 acres.

Heimos will continue producing floriculture crops—and hosting their popular poinsettia trials, we presume.

Heimos will continue producing floriculture crops—and hosting their popular poinsettia trials, we presume.

AO: Some things I’ve read recently make me think we may already be overproducing hemp for CBD oil. Prices and demand could plummet. Do you worry that this won’t be the long-term lucrative business you might hope?

Bernie: This is why we are making this a branch of our business and not our complete business. It will provide three turns a year with the space, and at the rate growers are closing or switching [from flowers to hemp], our space is in demand. This industry has only proven one thing to us: You either change with the times or fall behind. We want to grow relevant crops, and this is the new frontier.

Why “feminized” seed?

I never grew pot in my college dorm room, so I know nothing about the hows and whys of cannabis production. To find out why someone would want female seed rather than male, I went to my cannabis expert, Dr. Brian Corr, author of our "Corr on Cannabis" column in GrowerTalks (and who also never grew pot in his dorm room).

According to Brian, feminized hemp seed is seed that has been produced in such a way that all of the plants grown from the seed are female (in practice most, but not truly all, he adds). “Normal” cannabis seed produces plants with a 50:50 ratio of male to female.

Why are female plants good and male plants bad? Because if there are male plants present, the female plants will get pollinated and produce seed, and when plants produce seed, the cannabinoid content (CBD—the useful oil) is much lower. Plus, male plants tend to have lower levels of cannabinoids than females. Without males present, the female plants make no seed and lots of oil.

As for the importance of feminized seed, Brian sent me a link to this article about a lawsuit filed by a Kentucky grower claiming $44 million in losses after an Oregon hemp seed producer sent them more than 6 million seeds that were mostly males instead of feminized, as promised.

Brian taught me one more thing that I didn’t learn in college: the term “sin semilla” is Spanish for “without seed.”

One “orange” petunia that may not return

Last time, I reported the news that USDA-APHIS is considering a petition to allow petunias with the orange color-inducing corn gene in them (if you are completely lost, click HERE for the backstory). While writing that piece, I planned on referencing Supertunia Raspberry Blast because it was the best-selling of all of the 100-plus petunias caught up in the orange gene fiasco.

In fact, learning that it was Proven Winner’s fourth-best-selling petunia and seventh-best-selling variety overall, I assumed the company would be champing at the bit to bring it back, should APHIS rule in favor of deregulation.

I was wrong.

I asked Proven Winners’ Mark Broxon for his thoughts on the situation as it regarded Raspberry Blast, and his reply was, “Proven Winners’ position is that we don’t sell items that are GMO.”

Huh? You mean, even if APHIS okays the orange gene, you won’t bring back Raspberry Blast?

“That is correct,” he replied, adding, “Just FYI, Raspberry Blast is a variety that is licensed to Proven Winners, so we are not the ultimate decision maker on that one. However, there were one or two other items that we also pulled from the market when the GMO situation became clear. We would want to read the final APHIS decision to see if it changed our thinking at all, but at this time would have no plans to bring those varieties back to the market, nor any new items.”

Ah! So the door is a tiny bit open!

Proven Winners' decision brings up an interesting point: those orange-gene petunias are technically GMOs, meaning they are potentially a societal hot potato. Companies will have to think about that before introducing—or reintroducing—varieties of which the public now knows the genetic status. A dilemma for sure!

What are your thoughts on the situation, and why? Should Proven Winners and other plant marketing companies take a hard non-GMO stance with flowers to avoid potential consumer backlash? Or should they market GMO plants with the confidence that the USDA has deemed them legal and safe?

Email me HERE with your views.

Upcoming webinars: Nursery Weeds; Perennials in HydraFiber

I’m hosting two excellent webinars in October. Check them out and sign up at www.growertalks.com/webinars.

Improving Nursery Weed Control with Herbicide Rotations and Production Practices

Thursday, October 3

1 p.m. Eastern/Noon Central

In this free, hour-long GrowerTalks webinar, you’ll learn more about:

- Preemergence trial results with 25-plus herbicides and combinations, including traditional and recently released products

- Effective preemergence options for key troublesome weed species

- Selecting the best herbicides for your product mix and developing effective rotations

- Proven non-chemical strategies for herbicide-sensitive crops

My guest experts are Chris Marble, Ph.D., Assistant Professor—University of Florida, Mid-Florida Research and Education Center; and Aaron Palmateer, Ph.D., Senior Technical Services Representative for Bayer

The “A to Z” of Growing Perennials in HydraFiber

Thursday, October 17

1 p.m. Eastern/Noon Central

In this free webinar, perennial expert Paul Pilon of Perennial Solutions Consulting will share his observations of various perennial crops grown in HydraFiber and the feedback he’s received from growers across the country. You’ll also get his “keys to success,” including:

- Uniform blending

- Filling guidelines, including initial moisture content

- pH management and how to determine how much lime is needed

- Managing moisture in production

- Long-term vs. short-term crops

- Overwintering in HydraFiber

Joining Paul will be HydraFiber team member Daniel Norden, Senior R&D Manager and Technical Specialist Manager for Profile Products’ horticulture business, who will share recent Auburn University research on perennials and shrubs, plus results from several grower perennials trials.

Again, sign up for both at www.growertalks.com/webinars.

Don’t forget our Wage & Benefit Survey

If you haven’t done so yet, please consider taking a few minutes to fill out our annual Wage & Benefit Survey. There’s one for growers and one for retailers.

The information you provide is confidential and pretty general in nature (ranges, not exact dollar figure). It takes just five or six minutes total, but the info you provide is invaluable for helping us provide an accurate look at what the industry pays for various greenhouse and garden center staff positions.

Take the GrowerTalks grower survey HERE.

Take the Green Profit retailer survey HERE.

To show our appreciation for taking the time to help us, we’ll even put your name in for a drawing for a 128GB iPad!

A heartfelt thanks to Florasearch for being our long-time sponsor!

Finally ...

Ball’s Bill Calkins is working on a profile for Green Profit’s December Style Issue based on a discovery by our friend and columnist Art Parkerson: a company called Cinema Greens and a job called a greensman. Here’s what you might call a preview of coming attractions from Bill:

Just about any film set that includes trees, bushes, flowers, vines and living plants, in general, requires a specialized member of the film crew called a greensman. They handle every aspect of the greenery, including sourcing plant material from local nurseries, procuring faux plants from vendors, renting, planting and maintaining the green scene and getting very creative because often, the scene is not native or natural in any way.

Put it this way: directors and producers aren’t considering the natural bloom time of rose bushes when they ask the production designers to create a summer scene in Central Park … in Florida … in December.

That’s where the “greensman” come in—like professional film designer Bryan McBrien, the owner of Cinema Greens, and his team of experts. From Martian landscapes in movies like “John Carter” to the “Garden of Eden on a spaceship” in “Passengers,” the greenery and live plant material they source bring life to movies and TV shows.

Cinema Greens in Atlanta is a truly unique business because not only do they design the sets and procure the living and faux plant material, they also create amazing events and even sell some memorabilia used in hit shows and movies from their warehouse facility and a huge tow-behind plant trailer that visits local breweries.

See you next time,

Chris Beytes

Editor

GrowerTalks and Green Profit

This e-mail received by 23,841 loyal readers!

Thanks to my loyal sponsors, who help me reach the 23,841 readers of Acres Online in 66 countries. Want to be one of them (a sponsor, that is)? Give Paul Black a shout and he'll hook you up.