Organic Herb Production Guide

Call it more of a comprehensive overview of organic herb production, updated from a previous publication by the ATTRA Sustainable Agriculture Program, managed by the National Center for Appropriate Technology (NCAT).

The guide is free to download and costs $3 for a print version, available by clicking HERE. In it, the ATTRA details the U.S. herb market, suitable herbs for organic greenhouse production, some production methods, IPM programs, pests and diseases and possible controls.

If you’re exploring converting ornamental space into organic herb production, this is a nice start to help make your decision.

Labor: Your Thoughts

In the last edition of Inside Grower, I asked for thoughts about minimum wage and labor issues in general. I talked about a story detailing multiple cities raising their minimum wage, but it didn’t link. Click HERE to read that story.

I received several thoughtful responses and it sounds like labor is going to be an issue we face for a long time to come. Here are some of the responses, edited for length:

“There’s quite a push on for raising the minimum wage to $15 an hour. A recent Letter to the Editor in our newspaper pointed out that this is equivalent to 25 cents per minute. So if you see someone not doing useful work for four minutes, you are paying them a dollar to do nothing. Our green industry isn't paying that kind of wage, but even at half that rate, an eight-minute gap in productivity costs a dollar. With the required contributions to benefits, workman's comp, etc., it adds up. So the issue of hiring good quality workers is an important one for productivity. Do today's new entries into the workforce understand the concept?”

—Richard Criley, Emeritus Professor of Horticulture at University of Hawaii

(Editor’s note: Richard clarified in a later email that he is not against a $15/hour wage, but productivity has to keep up.)

“We have made a decision to pay what our city defines as a minimum livable wage. We also share 15% of pre-tax profits for all employees after one year of employment. We have trouble hiring people even with all this and health insurance paid at 75%. Friends in Europe see the same problem. There is little respect for physical labor among the younger generations.”

—Joel Pesapane, certified landscape professional

“We run a landscape and garden center in central South Dakota. We have a severe labor shortage; for the last several years our unemployment rate has been below 2%. Economists say full employment (i.e., those who want a job have a job) is 3%. To summarize, we have very few unemployed workers in central South Dakota. The companies that have good people are already paying them much more than minimum, the social welfare programs pay even more than that, and so any change in minimum wage will have absolutely no impact on our ability to hire.

We have several projects we'd like to start (off-season food production starting with leafy greens and citrus, roadside local grown food stand, mushroom production) that we're delaying or implementing very slowly because we're not sure if we can get enough qualified and trustworthy people to run them. The surrounding community interest and support for these endeavors is tremendous. The workforce availability is not.”

—Art Smith, East Pierre Landscape & Garden Center

Want to weigh in on the discussion? Email me at jpolanz@ballpublishing.com

MightyVine to Double Size

Business has apparently been good for Rochelle, Illinois-based MightyVine, a hydroponic tomato grower, as news comes out this week of its plans for expansion.

According to a July 31 story in The Chicago Tribune, MightyVine plans to double its size in response to demand from its large customers, which includes Costco, Walmart and Jewel-Osco. Chairman Jim Murphy told the media outlet they will break ground in September on a $16 million expansion project that includes two 7.5-acre greenhouse bays, bringing its total to 30 acres under glass.

This is the second major expansion for the company, which started in 2015 and harvested its first tomatoes for sale in 2016.

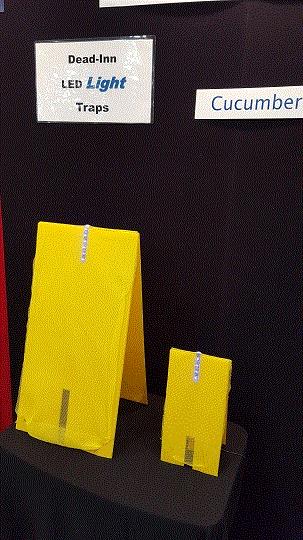

From Cultivate'18: Pest Control

I’ve gotten my notes pulled together from this year’s Cultivate’18 (finally!) and I’m ready to share a few new products that caught my eye. The first one is Dead-Inn LED light traps with D-Terrence from AgBio Inc. Basically the LED lights embedded in the screen attract winged pests at night, including aphids, fungus gnats and thrips. They fly to the screen, which is pre-treated with D-Terrence long-lasting insecticide, killing them on contact. The product is still pending EPA approval and is patent pending.

Dead-Inn LED traps from AgBio Inc.

From Cultivate'18 II: Hydroponic System

This isn’t an entirely new product, but I stopped at the Green Automation booth and took a look at some of the options available for automated hydroponic growing. This company from Finland offered two different systems, both of which are flexible and customizable depending on budget: the Fully Automatic System for baby leaf production, which features a more narrow gutter and a nifty germination area that “hides” under the main growing line; and the Automatic System designed for head lettuce or living lettuce.

Both are heavily automated, but the Fully Automatic System results in very few human touches (from filling media and seeding to transport through the system and through harvest and washing, the whole process is automated). Meanwhile, with the Automatic System, some manual steps are needed during transplanting and harvesting.

An example of the Automatic System from Green Automation.

New Bioinsecticide from Vestaron

My colleague JC Chong, who writes our PestTalks enewsletter (click here to sign up), wrote about Vestaron’s SPEAR-T Bioinsecticide for greenhouse applications, a product also spotted at Cultivate:

Vestaron announced on July 12 that Spear-T, a bioinsecticide, is now available for greenhouse use. Spear-T will be distributed by Isagro USA for the greenhouse vegetable market. Vestaron will announce additional distribution rights for the greenhouse market at a later date. The active ingredient of Spear-T is GS-omega/kappa-Hxtx-Hv1a. A mouthful, I know. But its history is nothing short of fascinating.

This active ingredient is based on a peptide in the venom of the Blue Mountains funnel-web spider of New South Wales, Australia. Folks at Vestaron identified the genes responsible for producing the peptide. They inserted the genes into yeast and mass produced the peptide in fermentation tanks.

The mode of action of Spear-T is unknown, but earlier studies on various insects and mites suggested that it's likely a neurotoxin. Two potential targets of the active ingredient are a voltage-gated calcium channel and a calcium-activated potassium channel. The intoxicated insects first contract their limbs uncontrollably, causing them to lose movement coordination and finally results in paralysis and death.

Unlike the original venom, which is injected by the fangs of the spider, Spear-T works by contact. Its targets include broad mite, thrips, twospotted spider mite and whiteflies. Additional pests may be added in the future. REI is 12 hours.

"World's Largest" Vertical Farm to be in Dubai

It’s always fascinating to me to hear about new ventures popping up across the globe and the latest one in Dubai is—in typical Dubai fashion—very ambitious.

CropOne and Emirates Flight Catering (EKFC) has plans for a 130,000 sq.-ft. indoor vertical farm (the world’s largest so far) in which they hope to grow 6,000 lbs. of greens and herbs under LED lights for flights leaving Dubai International Airport. According to this Business Insider story, EKFC caters for Emirates Airlines and all the other airlines at the airport, making it one of the world’s largest airline catering operations.

They will break ground in November 2018 with the plan of providing greens and herbs by December 2019 for 105 airlines and 25 airport lounges, according to the story. Interestingly, CropOne already has a vertical farm in Millis, Massachusetts, and delivers locally there under the Fresh Box Farms brand.

What’s also interesting is the partnership CropOne has made—EKFC provides a steady customer base and constant demand for the farm. The story also notes challenges other vertical farms and companies interested in such ventures have faced, including the tidbit that Panasonic and Google have both abandoned vertical farm projects in the U.S.

Keeping Product Fresh

I’m always impressed with unique, new ideas that come from simple beginnings. Such is the case for a product called FreshPaper, an idea that started as a middle school science project for founder Kavita Shukla. The product, inspired by Kavita’s grandmother’s blend of tea spices, infuses “organic, active botanicals that keep fruits and veggies fresh for up to two to four times longer,” according to the company’s website.

The paper is designed to be dropped into a bowl of fresh fruit or a produce container. It’s a low-cost, biodegradable and compostable paper that’s active for one month and can be stored for up to two years in the packaging. She’s been working to market the product for a while, but it’s now gaining steam and attention. Well deserved and I hope we continue to look for ways to reduce food waste and packaging waste.

Click the image to watch a video about the product.

As always, feel free to email me at jpolanz@ballpublishing.com with comments, questions, news and views.

Until next time,

Jennifer Polanz

Editor-at-Large

Inside Grower

This email received by 26,614 loyal readers!

Interested in advertising in Inside Grower? Contact Paul Black or Kim Brown and they'll show you how easy, effective and affordable it is.