Robots in the Greenhouse

A couple of weeks back AppHarvest announced it had acquired Root.AI, an agtech company that specialized in robotics and artificial intelligence (AI). I reached out to see if I could get some thoughts on what this means for AppHarvest, both in the existing farm in Morehead, Kentucky, as well as in future facilities (more on that in a minute).

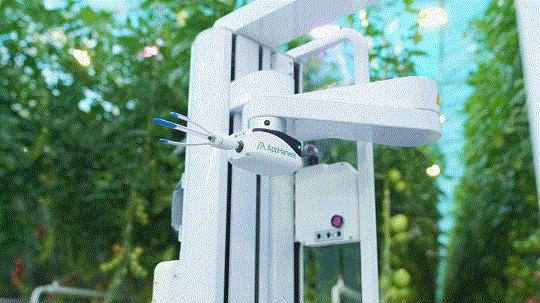

Virgo, the new harvesting robot at AppHarvest.

Here’s a short excerpt from some questions I sent to new Chief Technology Officer Josh Lessing (also one of the founders of Root.AI). Stay tuned to the next Inside Grower supplement, where we'll take a deep dive into this topic.

Q: How many “Virgos” (robots) will you deploy to begin with at the AppHarvest range and what’s the plan for growing that number?

JL: For now, we project one robot per acre in our first 60-acre vine crop facility. Our universal harvesting system is the first step to offering growers fully integrated, highly efficient AgTech solutions. We will be working to develop Virgo’s harvesting capabilities to help growers with crop yield predictions, plant health assessments and insights for optimizing their supply chain.

Q: How does Root.AI’s technology factor into the bigger picture of addressing labor shortages and impact AppHarvest’s goal of paying a living wage to workers?

JL: The robots will supplement, not replace, our current human crop care specialists, whether that’s while the crop care specialists perform other more skilled duties like pruning, trussing or de-leafing. Robots also could help manage workload during peak harvest times.

The value of the AI and robotics technology is that it makes our entire operations more efficient through the data that the robots collect as they harvest. We expect to leverage that data for insights to optimize our CEA facilities. The data feeds into AI and keeps making models more accurate to learn how to grow and harvest most efficiently.

Do you have robots working in your greenhouse? Or are you considering taking the leap? Let me know at jpolanz@ballpublishing.com.

AppHarvest Update

Speaking of AppHarvest, the company released the results of its first completed quarter as a publically traded company and a couple of announcements came with it.

One, the company plans to expand rapidly, ambitiously announcing there will be five farms operating (my emphasis) by the end of 2022, and as many as 12 farms by the end of 2025. Those farms will also grow berries and leafy greens along with tomatoes.

Second, the company confirmed it's now shipping tomatoes not only to grocery and food service outlets, but also to retailers Wendy’s and Kroger.

You can read the full investor press release HERE.

Cannabis Research

You may have heard the news announced last week that the DEA is finishing its review of applications for marijuana research and will be opening up new opportunities for research soon. Prior to this, only one institution, the National Center for the Development of Natural Products at the University of Mississippi, has been allowed to research marijuana and only for the National Institute for Drug Abuse.

I wondered if opening up the ability to research marijuana would benefit growers in any way—as in, would this allow researchers to develop better growing methods? I reached out to our GrowerTalks and Inside Grower cannabis expert Brian Corr to ask. The simple answer? No.

Here’s his answer:

Many researchers have questioned whether the cannabis produced under the government program at the University of Mississippi was representative of cannabis available to the average user. The Mississippi program produces freeze-dried cannabis that is ground to a uniform size. This is quite different from what is typically sold through either state-legal channels or on the black market.

The goal of the DEA program is only to make THC-rich cannabis available to the research community. This is important, since we need better understanding of the effects of cannabis on human health, both for good and for bad. However, it does little to advance the horticulture of cannabis production.

Classic horticulture research on how to grow cannabis is advancing, but slowly. Here in the U.S., study of the horticulture of cannabis production is stymied by federal regulations, which cause research institutions to only study production of cannabis with a THC content below 0.3%.

Most universities would not risk conducting any research on cannabis production prior to the Farm Bill of 2014, which allowed limited cannabis production research. The Farm Bill of 2018 defined cannabis with a THC content below 0.3% as "hemp," which opened more research options. Horticulture research can be conducted with "hemp" cannabis without running afoul of federal regulations.

The American Society for Horticultural Science (ASHS) has been one of the outlets for bringing that research to light. ASHS publications have published over 60 research reports on cannabis in the last several years. Last year, the annual ASHS conference included over 30 oral or poster presentations regarding cannabis and the ASHS conference this year will include even more. The 2018 Farm Bill is allowing researchers the freedom to conduct the sort of research that makes other horticultural crops successful, even if it still restricts research to only low-THC cannabis.

Thanks for the insight, Brian! Check out ASHS for more on this year’s conference.

Are You Feeling the Effects of a Pallet Shortage?

United Fresh Produce Association recently put out an alert about a pallet shortage that could cause serious issues with fresh food production. There are multiple reasons for the lack of availability, according to the organization, including:

-

Efforts of wholesalers, distributors and retailers to ensure sufficient inventory of non-perishables given previous pandemic-related impacts

-

The availability of lumber to repair and build new pallets

-

The escalating price of lumber when it's available

-

Non-perishable inventory dwell time increase

-

Lack of available trucks to relocate pallets

The issue has been causing major price increases, as well as delays. Here’s some info compiled by United Fresh:

-

The shortage of lumber and wood products has increased the cost of raw lumber 200% to 350% and is making the cost of wood pallets increase incrementally.

-

In one example, it was noted that over the past few weeks, pallet costs have increased more than 400%, IF the pallets are even available, and often they are not.

-

One farmer was told by one pallet supplier that they aren't taking any new customers due to an inability to fill even existing customer demand.

-

Companies are forced to bring pallets from other jurisdictions, thereby incurring border and transportation costs.

-

Pallets are being held in-house due to delayed and cancelled orders from pallet services, leading to higher storage charges and increased congestion within operations.

You can read the full alert HERE. Are you experiencing difficulties or increased prices related to pallets? Drop me a line at jpolanz@ballpublishing.com and let me know.

Supply Chain Solutions

Shortages of required materials are just one link in the supply chain. United Fresh Produce Association will be talking about everything from planning for uncertainty and change to transportation, cold chain management and workforce needs at its new Reimagine Conversations sessions happening in June.

There’s a whole track of five sessions on overcoming supply chain challenges. Here’s the schedule:

Friday, June 4, 11:00 a.m.-Noon Eastern: Worker Safety Requirements—What You Need to Know

Friday, June 11, 11:00 a.m.-Noon Eastern: Filling the Needs of the Post-Harvest Workforce: An Industry Roundtable Discussion

Friday, June 18, 11:00 a.m.-Noon Eastern: Transportation for the Future

Friday, June 25, 11:00 a.m.-Noon Eastern: Understanding Technology for Cold Chain Management Success

Tuesday, June 29, 2:00-3:00 p.m. Eastern: Planning for Uncertainty and Reacting to Change

Other track topics in the Reimagine Conversation include Produce Safety; Retail and Food Service; Produce 101; and Marketing. All are happening throughout the month of June. CLICK HERE for full details.

Leafy Greens Research

In this space a while back I reported on a project funded by USDA involving six researchers at four universities called OptimIA (Optimizing Indoor Agriculture). Now, that partnership is producing research on indoor leafy greens production that can be accessed by growers everywhere.

CLICK HERE to find the latest published research by the group, as well as trade articles, recorded webinars and upcoming events.

The research is a result of studies by six horticulture, engineering and agricultural economics professors and extension specialists, their graduate students and technicians at Michigan State, The Ohio State and Purdue Universities, and the University of Arizona. The funding comes from the USDA Specialty Crop Research Initiative as part of a four-year grant designed to help growers overcome the technological, environmental and financial challenges of indoor growing.

“The OptimIA project’s ultimate goal is to define the environmental parameters within which leafy greens, such as lettuce perform best in indoor vertical farms,” reads the release provided on behalf of the group by Dr. Roberto Lopez of Michigan State. “While the work of each project researcher is unique, all centers around the effects of light, carbon dioxide, humidity, temperature, air movement and economics (operating, labor, equipment, etc.) on the sustainability and profitability of using indoor farms to produce leafy greens and microgreens.”

As always, feel free to email me at jpolanz@ballpublishing.com with comments, questions, news and views.

Until next time, stay safe and be healthy,

Jennifer Polanz

Editor-at-Large

Inside Grower

This email received by 28,198 loyal readers!

Interested in advertising in Inside Grower? Contact Paul Black or Kim Brown and they'll show you how easy, effective and affordable it is.