Disease Control Podcasts

I regularly hear from readers who listen to my Tech On Demand podcasts while working in the greenhouse, often listening to a few in a row throughout the day. If that’s the case with you and your listening habits, I want to suggest a previous three-part series that will help you this year as you move through the coming season.

Disease control is always a hot topic in greenhouse discussions, and last year I worked with tech whiz Dr. Aaron Palmateer to cover greenhouse disease from three angles.

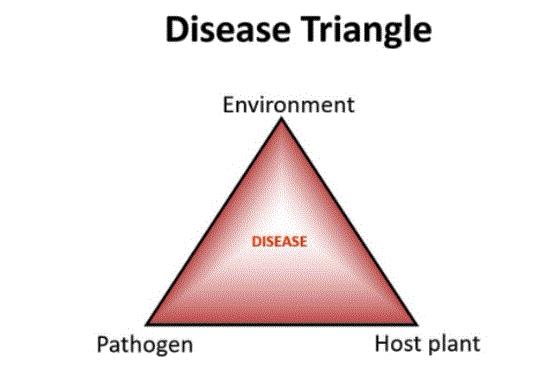

FOLIAR DISEASE: Aaron explains why leaf spot disease management must be a top priority for all greenhouse professionals. He also compares the importance of yield to farmers with quality for greenhouse growers. After setting the stage for this episode’s discussion, the conversation moves to the importance of diagnostics and then takes a deep dive into how exactly disease happens with a review of the “disease triangle”—with a twist. The differences between fungal and bacterial pathogens are detailed before we tackle best practices to avoid them.

ROOT, STEM & CROWN ROT DISEASES: Because some of the diseases discussed occur below the soil and out of sight, detection is extremely critical to avoid devastating effects to the crop. The sooner you detect symptoms, the better, and that’s how this episode begins. Next, Aaron moves to an overview of the major pathogens impacting root, stem and crown and exactly how they cause disease. He goes in-depth on the "Big Four"—Pythium, Phytophthora, Rhizoctonia and Fusarium—but also discusses less-common pathogens and fungi.

BUILDING A DISEASE MANAGEMENT PROGRAM: The episode kicks off with an explanation of integrated management for pests and diseases before moving into the key components for a solid program. Once the basics are covered, Aaron shares specific strategies to build a program and ways to know exactly what you’re dealing with when it comes to your crop plan. We wrap up with a conversation about the many variables that exist each season and methods and protocols to follow to minimize the risk of introducing diseases (as well as pests and weeds) into your production environment.

Nick's Tip of the Week: Getting Ready for Garden Mum Season (Part 1 of 5)

Each week, I’ll work with my buddy Nick Flax, a technical services expert at Ball, to share a concern that’s come up during one of his numerous calls with growers across North America. This week, he’s kicking off a five-part miniseries on garden mum production.

PROBLEM: Now that we’re past Mother’s Day and spring bedding plant sales are going strong, don't let your fall garden mum program sneak up on you. Mums may be low on your list of priorities right now, but take a moment to go through your checklist and make sure you’re all set for your cuttings or liners to arrive.

Assuming you have pots and media to plant into, there are two main things that you should ensure you have on hand to produce a top-quality mum crop this year: disease management tools and appropriate fertilizers. Let’s start this week by covering diseases to watch out for and good management strategies for each one.

NICK’S TIP: Garden mums can be affected by a diverse range of pathogens, but there are a few diseases that I get lots of calls and emails about from growers each year. Northeast growers should have a strong preventative program in place for Chrysanthemum White Rust (a USDA quarantinable pathogen; more info here), but the major mum diseases that growers everywhere should monitor for and manage judiciously are Pythium, Fusarium, Botrytis and bacterial leaf spot.

Pythium

The best practice for managing this disease is to start prevention as early as possible. Apply a root zone protectant about 7 to 10 days after planting liners or once roots have reached container sidewalls.

-

Reapply at appropriate intervals (per the label) to ensure constant presence of a root zone protectant.

-

Consider reapplying at shorter intervals within the prescribed range if the crop is being grown outdoors under persistent rainfall.

Damaged roots provide an entry point for infection. Regularly check the root zone for desiccation damage, discoloration, and “clubbing” root tips from high soluble salts (EC).

-

Avoid drying your crop down too hard and check soil moisture levels at least twice a day. Check your edges and corners, especially on south and southwest-facing sides of production blocks, and “edge-water” as needed.

-

Monitor soluble salt levels (EC) in your growing media and leach the crop if necessary to avoid damaging roots.

-

If plants are on drip irrigation, place drippers (or at least one, if you have multiple per pot) on the south-facing side of the container. This will help keep the growing media “hot zone” cooler on hot, bright days and reduce potential damage to roots due to extremely heat.

Biologicals (ex. Trichoderma-based products and others) work best when applied before disease occurs and have limited efficacy when applied reactively once disease strikes.

Traditional chemistries for controlling Pythium (etridiazole, mefenoxam, thiophanate-methyl, etc.) are also most effective when used preventatively; they will likely be more robust solutions to high or persistent disease pressure. For example, if Pythium is present in your water source (for example, if you irrigate from a retention pond), traditional chemistries may prove to be the better option.

Next week: Fusarium!

Quick Tech Tip: Fern Production Best Practices

In a recent issue of GrowerTalks, a fern specialist at Casa Flora, Inc. shared SIX SECRETS TO SUCCESSFUL FERNS, and I thought it would be good info to include this week. Shanti Claycamp and the folks at Casa Flora grow more than 80 varieties of fern liners and are definitely experts in the field. Growing ferns is not too challenging for most of you, but these six tips are good refreshers and certainly valuable to share with your production team. Click the link above for the full story.

-

Always check the hardiness zone on fern varieties to make sure they’re appropriate for your area or the areas where you’re shipping.

-

Ferns prefer moist soil (but not level 5), and even aeration in your media is the goal. Choose your mix wisely.

-

Shanti recommends 65 to 75% shade in production. Too much sun leads to sunscald on many varieties.

-

Ferns are not heavy feeders and perform best with a balanced feed like 20-10-20 or 20-20-20. Don’t overfertilize or let reside accumulate on the fronds.

-

Ferns don’t come under attack from too many pests but watch for caterpillars and fungus gnats.

-

Many hardy ferns lose foliage in the winter and bounce back in spring. Deciduous ferns should be cleaned up and dead foliage removed, while semi-evergreen ferns should not be trimmed until spring. Know your varieties to make the best decision on trimming.

Do You Have a Sanitation Strategy?

Each season brings new crops and the opportunity to clean up your greenhouses as they empty out. Hopefully, you have some sort of plan and protocols for sanitation between seasons. If so, fantastic. If not, you definitely should! It's a good idea to take some time to run through your plan before each season. Here are a few resources to help get your sanitation strategy in order so you’re ready to rock and roll the next time you are between crops.

Video: GET PREPARED—FROM CLEANUP & MAINTENANCE TO PLACING ORDERS is a Tech On Demand In the Break Room video featuring Dr. Todd Cavins that covers sanitation and preparation from a few angles, including what to clean and how to clean, as well as equipment maintenance and even some pest and disease control strategies.

Article: In START CLEAN. STAY CLEAN, I took the video a step further and worked with Todd to create a much more thorough plan for greenhouse sanitation. No matter the size or shape of your greenhouse, you need an organized, systematic approach to sanitation, especially between seasons. As Todd says, “Get robotic about it. Make it boring.” Every day, it should be part of the system. The good thing is that simple cleaning requires little time and labor, and results in major gains in terms of reduced plant losses. In the article, we look at greenhouse sanitation best practices, as well as activities and methods that will help you stay on top of cleanliness.

Article: SANITATION—INSECT PEST MANAGEMENT IN GREENHOUSES, an article by Dr. Raymond Cloyd and Research Associate Nathan Herrick at Kansas State University, digs deeper into the importance of cultural control strategies and sanitation to minimizing the risk of pests negatively impacting your crops. Reducing the opportunities for pests to inhabit your production areas leads to reduced pesticide use, which in turn minimizes the risk of resistance and other challenges. This article is a fantastic look into best practices and new practices for you and your team.

Poinsettia Cuttings: Start Clean with a Dip

Following up on the last item about starting clean, I was reminded of something my Ball Publishing e-news colleague JC Chong wrote in PestTalks recently. He mentioned being about to receive some poinsettia cuttings for a research project in his Clemson greenhouse and went through some protocols for reducing the risk of whiteflies. JC discussed pre-plant dips in an insecticidal soap and horticultural oil mixture as not only reducing whiteflies early in the crop but also helping increase the success of future biological control programs. Here’s what he wrote:

I’m going to place an order of poinsettia cuttings next week to get ready for research projects. Research for what? Killing them whiteflies, of course. For y’all who are getting cuttings, I want to remind you to inspect them for whitefly nymphs and eggs. Even if inspection finds no whitefly nymphs (eggs can be too small to miss), I encourage dipping the cuttings in a mixture of Beauveria bassiana (Botanigard 22WP at ½ oz. per gallon), and 0.5% insecticidal soap (M-Pede) or 0.1% horticultural oil (such as SuffOil-X) before sticking them. This pre-plant dip method has been proven effective in suppressing whitefly populations in the first eight weeks after sticking in research projects conducted independently by Dr. Rose Buitenhuis, me and several of our colleagues. A VIDEO and a written GUIDELINE of proper dipping procedures are available.

Pre-plant dip also makes biological control programs more successful by reducing the initial whitefly population. This gives biological control agents, be them predators or parasitoids, a chance to catch up to the whiteflies.

I’ve been touting the benefit of pre-plant dips for some time. One of the most frequently asked questions is, “Do the workers dipping the cuttings and sticking the cuttings have to wear PPE (personal protective equipment)?” This is actually a two-part question.

First, yes, the person preparing the dip solution and making the dip is an applicator and, therefore, must have the proper training and wear PPE. PPE required for pre-plant dips with Botanigard, SuffOil-X and M-Pede are coveralls, chemical resistant gloves and shoes plus socks. PPE for other products containing B. bassiana, horticultural oil and insecticidal soap are outlined in the product labels.

As for workers who stick the cuttings, their requirements may be different depending on when the sticking occurs. If the sticking process occurs during the restricted-entry interval (or REI, which are four hours for Botanigard and SuffOil-X, and 12 hours for M-Pede; always go with the longest REI in the mixture), the workers should receive training on Worker Protection Standards (WPS) and wear appropriate PPE.

If sticking occurs after the REI, no specific training or PPE is needed, but I would still encourage WPS training and PPE use. Understand that states can place requirements or restrictions in addition to what’s required under the WPS, so check with your local pesticide regulator or state department of agriculture for specific requirements and restrictions.

FREE Webinar on NEW Breeding Technology

On Tuesday May 24, join host Chris Beytes at 1:00 PM Eastern Time for a free webinar title Intrinsa: Plants Powered for a Greener Future.

New technology from the Dümmen Orange breeding technology center has led to "Intrinsa breeding," which they say leverages a plant's natural genetics for advance disease resistance, better plant performance and more economical (and sustainable) crops for the future. In a scientific nutshell, Intrinsa combines genotyping with phenotyping using the genetic map of a species and genetic markers to speed up the traditional breeding process. High-tech stuff, for sure!

Chris will be joined by presenters Stephanie Whitehouse (Regional Product Manager–Decorative Annuals) and QiuXia Chen (Regional Product Manager–Garden Mums) to explain this breakthrough in breeding and how it will benefit you, the grower. REGISTER NOW!

Finish Line ...

If you’re reading this, you obviously receive my weekly newsletter … but did you know Ball Publishing produces TEN e-newsletters, each covering a specific topic or market segment? That’s right, ten opportunities either weekly or bi-monthly to read timely and relevant news items and stories squarely focused on your business interests.

From perennials to tropical plants and cut flowers to controlled environment agriculture, our experienced editors have the best connections in each market to bring you cutting-edge info. As you read above, PestTalks is written by a PhD entomologist—you really can’t get any better than that! Nursery & Landscape Insider is penned by another professor who teaches nursery management courses. Acres Online, by the one and only Chris Beytes, is longest-running of the group (since December 2003!) and covers all of the latest happenings in the professional greenhouse world. On the flip side, buZZ! is the retail newsletter from Ellen Wells tackling everything garden center-related.

I honestly could go on and on about our e-newsletters because each one is a leader in its field and each editor is passionate about the topic they cover in their own unique way. I’m proud to be a member of the group.

CHECK OUT ALL OF OUR NEWSLETTERS—sign up to receive the ones you need. And jump back in the archives to read past issues.

Have a fantastic week!

Please feel free to send your comments, constructive criticism and topic ideas to me at bcalkins@ballhort.com.

Bill Calkins

Editor - Tech On Demand

This email was received by you and 25,728 other fine subscribers!

If you're interested in advertising in Tech On Demand, contact Kim Brown ASAP and she'll hook you up.