9/30/2025

AI: Gaining Back Time

Clint Albin & Carl Hildebrandt

In our last article, we discussed how AI is already reshaping local green industry businesses. Procurement, the true lifeblood of any garden center, demands precision. Retailers have a chance to stop reacting to procurement problems and start automating them.

Procurement is the garden center’s circulatory system. A single SKU can pass through buyers, receivers, greenhouse staff, merchandisers and cashiers before reaching the customer. Every handoff introduces risk—especially during peak windows when demand is perishable and customer expectations are high. Many retailers are still running this gauntlet with spreadsheets, handwritten slips and institutional memory.

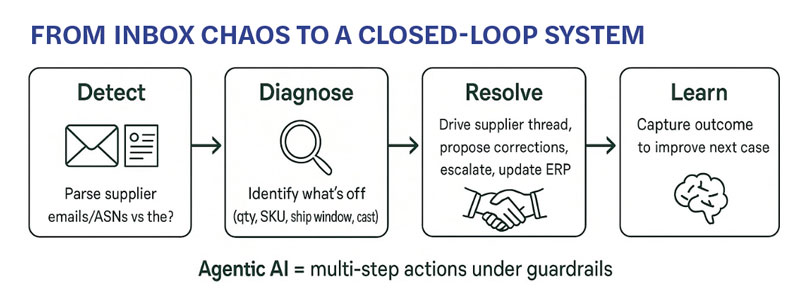

Traditionally, a short shipment could trigger a dozen back-and-forth emails, leaving inventory stalled in the backroom and profits waiting on the sidelines. AI changes the equation. Acting like the operations assistant every retailer wishes they had, it instantly flags discrepancies, identifies root causes, drives communications, insists on a resolution, and proposes corrections in almost real time.

The result is procurement shifts from reactive headache to proactive system, moving plants and products onto the sales floor faster and strengthening the bottom line.

Procurement, Optimized: Less Scramble, More Margin

Procurement processes have evolved far beyond just placing orders. Today, the process entails orchestrating a complex web of suppliers, fast-moving timelines and seasonal urgency. A single SKU may pass through buyers, receivers, greenhouse staff, merchandisers and cashiers before even making it to a customer’s hands. And each handoff introduces the potential for friction, delay or error.

This complexity is magnified by tight selling windows and high customer expectations. Retailers must constantly make rapid, yet informed, decisions to stay competitive and in-stock. Spring is a prime example. In just 12 weeks, garden centers navigate six micro-seasons, each with its own inventory demands and timing pressures. A missed delivery or incorrect quantity doesn’t just inconvenience staff; it can derail revenue at the most critical time of year. Yet many garden centers still rely on outdated and manual processes like spreadsheets, emails, handwritten slips and even memory. These tools are prone to error, and miscommunication often creates operational headaches.

AI is being constructed and refined to eliminate these kinds of problems. In real time, it can analyze supplier communications, flag discrepancies and recommend corrective actions, enabling smarter, more agile operations. These insights would otherwise be buried in inboxes, spreadsheets or siloed systems.

Agentic AI is one type of AI being designed as a tireless assistant that can help transform business processes, like procurement, from a reactive scramble into a systematized, proactive approach. Take Epicor’s agentic AI, Prism, for example. It is a network of vertical AI agents being rolled out across the make, move and sell industries that works to quickly source and provide the best answer or recommendation to a user via simple, natural language queries. One agent, for example, enables users to initiate, track, and resolve RFQs, order discrepancies, and supplier inquiries directly through email communication without logging into separate portals or different interfaces.

Because it understands Epicor’s unique ERP data structure, the AI agent can carry on a conversation with a user and contextually translate email communications with suppliers, such as “lead times,” “cost” and “part ID” directly into the ERP. This eliminates the need to toggle between email threads, spreadsheets and external systems, allowing procurement and operations teams to collaborate faster and with greater transparency.

By streamlining communication from sourcing to delivery, the AI communications strategy ensures that the intelligence gained is matched by the speed and clarity of execution. When procurement runs smoothly, inventory moves faster, shelves stay stocked and customers find what they came for. The result? More time to focus on the customer, more time to find new products and more time to measure local business competitiveness.

But AI’s impact isn’t limited to the procurement process alone. It is being used to optimize labor management in the warehouse, too. It’s helping managers make easier, faster and more accurate staffing decisions with intelligent scheduling tools. Rather than relying on gut instinct or static schedules, managers can use AI scheduling to gain predictive insights that build smarter rosters, adjust shifts on the fly and assign tasks with precision. When your labor is synchronized, your products move faster, transactions increase, market baskets get larger, customer service improves and profitability rises.

Procurement and staffing are just the beginning. AI can optimize the entire product lifecycle, from order to invoice to shipments. By streamlining every operational touchpoint, AI also enables retailers to:

- Predict demand and automate replenishment

- Validate shipments and flag mismatches

- Accelerate merchandising to reduce backroom bottlenecks

- Simplify invoicing and reconciliation

The goal of AI though, isn’t just speed; it’s clarity. When retailers can see the full lifecycle of a product in real time, they make better decisions faster, and the business benefits.

Real-World Momentum from Epicor Research

According to the 2025 Epicor Agility Index, 56% of supply chain businesses report high AI readiness, and within that group over 90% are actively investing in AI-specific roles. This signals a broader shift. And it’s one that the retail industry can’t afford to ignore.

This transformation isn’t theoretical. Epicor sees customers across all industries who are already seeing measurable results from intelligent AI automation.

One manufacturer reduced support call time by nearly an hour per employee question by using an agent to quickly serve up answers in an easy-to-understand manner. Another manufacturer is using AI to analyze product lists, customer charts, ROI metrics and fulfilled orders that can cut delivery times almost in half. These aren’t just abstract metrics. They’re proof points that intelligent automation that focuses on existing systems drives real business outcomes.

But readiness isn’t just about technology; it’s also about mindset. Many independent retailers still view AI with some skepticism, especially in segments where digital transformation has historically lagged. Education is key. The conversation must move beyond fear and into strategy: How can AI help solve the problems you already face? How can it support, not disrupt, your existing workflows?

Retailers who embrace AI as a strategic enabler will be better equipped to navigate inventory mishaps, labor mismatches, seasonal volatility, rising competition and razor thin margins. The obstacle is shrinking, but the opportunity for innovation is growing.

The Way Forward

Independent garden retailers are at a pivotal moment. The pressures are real with compressed seasons, labor constraints and rising customer expectations. AI offers a way to rethink operations, reclaim time and refocus energy on what matters most: delivering value to the customer.

At Epicor, we see AI not as a destination, but as a journey. One that starts with solving real problems with business workflows, like procurement bottlenecks, and evolves into a broader strategy for agility, insight and growth. The future is embedding AI into the natural rhythm of operations, driving smarter decisions and enabling teams to do more with the resources they already have.

Retailers who lean into this transformation won’t just keep up, they’ll lead, grow and survive.

Next month we will focus on how to increase the number of touch points in the customer journey and, by extension, transactions. GP

Clint Albin is CEO of A24 Consulting and Carl Hildebrandt is vice president of product management at Epicor.