2/1/2024

Avoiding Crop Contamination

David Kuack

The Centers for Disease Control and Prevention (CDC) estimates that there are about 48 million cases of foodborne illness in the United States every year. The most common cause of these illnesses are foodborne pathogens, including bacteria such as Salmonella, Listeria and E. coli, and viruses, such as norovirus and hepatitis A.

Pictured: When possible, workers should have two sets of tools so they can sanitize one tool while using the other to continue working.

While food crop production in greenhouses or indoor farms might be considered safer than outdoor field production, plants can experience the same exposure to human pathogens regardless of where they’re produced.

The CDC reports many kinds of produce, including organic leafy greens, can be contaminated with human pathogens. According to the CDC, leafy greens produced with hydroponic or greenhouse-grown methods can also be contaminated with these pathogens at any point from farm to fork.

“Greenhouse and indoor farm growers think they are growing a safe product because they are growing in a controlled environment structure,” said Melanie Lewis Ivey, associate professor, Fruit Pathology & Fresh Produce Safety, and extension experience coordinator at The Ohio State University. “There is a difference between a controlled environment and a closed environment.”

Sources of pathogen contamination

Melanie said the risks of human pathogen contamination in controlled environment production systems overlap the risks that occur in field production.

“Worker health and hygiene present a risk. Another potential risk is the nutrient solution and the source of the water, and how it is handled and treated before it reaches the plants,” she said. “Also, if the water is recirculated, what happens to it after it is collected. With equipment, any type of contamination that comes in on the equipment is a risk.

“My colleague, Dr. Sanja Ilic, and I are doing research on what type of risks may occur from different substrates. We’re not sure yet whether the type of substrate can pose a contamination risk.”

And while there are plant pathogens that are seedborne, Melanie said they don’t have very good evidence that human bacterial pathogens are seedborne.

And while there are plant pathogens that are seedborne, Melanie said they don’t have very good evidence that human bacterial pathogens are seedborne.

“If the seed became contaminated there would be a chance that they could cross-contaminate a seedling or transplant, but the risk is very low,” she added. “We don’t have a lot of scientific data right now supporting the transfer of human pathogens by seed.”

Pictured: To prevent food crop contamination, workers in controlled environment production facilities should use best practices, including washing their hands frequently, changing or sanitizing their shoes with foot baths and/or wearing shoe covers.

Sanja, who’s an associate professor and food safety state specialist in the Department of Human Sciences, said microgreens, which are sprouted seeds, could pose a risk in transmitting human pathogens. They should be considered to the highest extent of contamination when growing them.

“The warm, humid conditions that are used to germinate these microgreen seeds are similar to the conditions that favor bacterial pathogens," Sanja said. “If the seeds are contaminated and the seed is pushing out its roots and stems, it is going to provide a surface for bacterial pathogens to grow.”

Lowering human handling risks

Humans are a limiting factor for food safety, whether crops are being produced in the field, greenhouse or indoor farm.

“Implementing hygiene practices that limit cross contamination or limit contamination from humans to the plants are very important,” Sanja said. “With greenhouse and indoor farms, it’s high-density planting in a small footprint. One of the advantages of controlled environment agriculture is a lot of food can be produced in a small area.

“But those crops get manipulated and handled a lot. Tomato plants are pruned, tied and harvested almost daily. Leafy greens in deep-water culture have to be removed from the ponds. Each one of those plants, in most cases, is harvested manually. There are people moving throughout the facility and if there is debris on the ground or floor, they move that around with them.”

Karla Garcia, who provides technical service at Hort Americas and is the CEO at Microgreens FLN, said workers are a significant risk factor to spreading human pathogens in controlled environment facilities.

“We recommend that growers use best practices, including having workers washing their hands frequently, changing or sanitizing their shoes with foot baths or wearing shoe covers,” Karla said. “Any practice that will keep workers clean, and practices that minimize handling of the plants and harvested produce. That can be difficult to do when growing fresh fruit and vegetables.”

Pictured : In a vertical farm, the racks or trays should be sanitized along with cleaning the floors, which can accumulate water, substrate and plant debris that can carry plant pathogens.

: In a vertical farm, the racks or trays should be sanitized along with cleaning the floors, which can accumulate water, substrate and plant debris that can carry plant pathogens.

It’s important to train workers to minimize touching the plants if it’s not required. If there’s a chance to spread pathogens like viruses, Karla added workers should wear disposable gloves and change them frequently. It’s also better if workers can have two sets of tools so they can sanitize one tool while using the other to continue working. Scissors are usually used to prune vining plants. Pruning opens wounds, which can allow some viruses and bacteria to be transmitted between the plants.

“Tools should be cleaned moving from one crop row to another,” she said. “Vining crops also need to be wired so clips are attached to the plants. For tomatoes, if the fruit is heavy, workers need to touch the plants to clip them. Because the plants are being touched so much, it is important that workers are washing their hands and wearing gloves.”

Don’t overlook equipment

Anything that’s brought into a greenhouse or indoor farm could potentially be a source of human pathogens, and has to be handled with care and stored properly to avoid any possible exposure to contamination.

“In any operation, whether it is a greenhouse or an indoor farm, rarely is any piece of equipment designed with sanitation in mind,” Sanja said. “The majority of equipment is designed to do a certain task, to serve a certain purpose. The equipment has not been designed to be opened, disassembled and completely sanitized. Some equipment like pumps and tubing cannot be sanitized. In an indoor farm or greenhouse that are using mechanical harvesting and robots to move plants, there is a risk of equipment contamination.”

Karla noted it’s particularly important to sanitize the equipment in a vertical farm.

“In a vertical farm, plants can be grown without pesticides, but if a problem occurs, it is going to be much more difficult to resolve because it is an enclosed system,” she added. “Vertical farm growers need to be very careful from the start to clean the equipment and tools with a sanitizer to kill any type of human pathogen that might be present.

“In a vertical farm, everything should be cleaned at least once a week, including the floors, because there can be an accumulation of water, substrate and plant debris, which can carry plant pathogens.”

Water source, treatment issues

Indoor farm systems are usually completely enclosed when it comes to water recirculation. Pond water and surface water have the highest risk of pathogen contamination. That risk decreases with municipal water.

“Because water is recirculated it is not only important to have a safe water source, but it is also important to maintain that source as safe,” Sanja said. “Water treatments are important, but these treatments are not always validated. Water can be treated with a chemical sanitizer or UV light and then put back into the irrigation system. Once a pathogen is in the system, what Melanie and I showed in our research is the pathogen travels with the water and establishes itself around the plant roots and remains there.

“Currently, there isn’t a water treatment available that is effective in systems with plants in them. We have tested chemical sanitizers and found sanitizers added to a system will affect plant health. These sanitizers can damage or kill the plants or at least impair plant growth to the point that they cause losses to yields.”

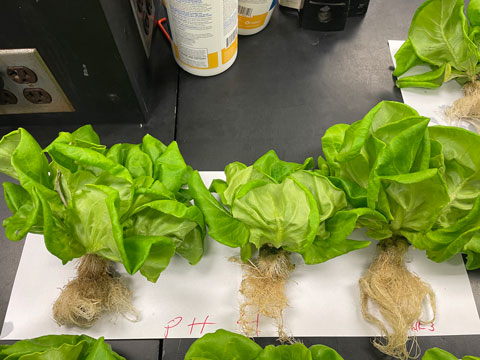

Pictured: The Ohio State University researchers Melanie Ivey and Sanja Ilic found that once a human pathogen is in a hydroponic recirculating irrigation system (NFT and deep-water culture), it travels with the water and establishes itself around the plant roots and remains there until the plants are harvested.

Pictured: The Ohio State University researchers Melanie Ivey and Sanja Ilic found that once a human pathogen is in a hydroponic recirculating irrigation system (NFT and deep-water culture), it travels with the water and establishes itself around the plant roots and remains there until the plants are harvested.

Research conducted by Sanja and Melanie with leafy greens grown with nutrient film technique and deep-water culture found that Salmonella and Listeria can persist in the systems and in the area around the roots for the entire life cycle of the plants.

“Our research showed the bacteria don’t increase, but they don’t tend to die off either,” Melanie said. “Once in the systems, these pathogens are carried with the recirculating water and become established around the roots and remain there until harvest.”

Contamination from animals

While workers are the primary carriers of human pathogens, growers should not overlook the potential risk coming from domestic or wild animals.

“Any sort of exposure to animal materials—including manures, feces from domestic wildlife, etc.—could potentially serve as a contamination source,” Sanja said. “Although people usually perceive a controlled environment to be less exposed to certain risks, it is not completely protected from animal life. Pets and rodents can be original sources of contamination. The transmission can occur through crop contamination; if sanitation is not done regularly and properly, these pathogens can become established in the environment and then contaminate the plants. Once pathogens are in the production system it can be very difficult to eliminate them unless a complete shutdown and sanitation of the operations occurs.”

Melanie said there’s a misconception that wildlife isn’t a problem in greenhouses or indoor farms.

“Birds and rodents can be introduced into these facilities,” she said. “They are potential carriers of human pathogens.

“Contamination of food can occur anywhere during the production, handling and harvesting of a crop. Sanja and I focus on mitigation basically at every step of production. The dosage that is required to make someone sick, especially if they’re immunocompromised, is low. Not a lot of bacteria cells, such as Salmonella or E. coli, are needed to make people sick. The goal is to prevent the initial contamination of these controlled environment systems and limit proliferation of the pathogens.”

Best Management

The Ohio State University’s Fruit and Vegetable Safety Team offers an online course called “Good Agricultural Practices for Food Safety of Hydroponic Crops.” This self-paced course provides controlled environment food growers with the information and tools needed to implement best management practices to reduce microbial food safety hazards.

David Kuack is a freelance technical writer in Fort Worth, Texas. He can be reached at dkuack@gmail.com.