2/1/2024

Cutting Storage: A Useful Space & Time Management Tool

Ashley Canaday, Kathryn Gathers, Dan Greco, Lydia Owens & James Faust

The standard procedures for the cannabis industry are to grow large stock (mother) plants and harvest a relatively low number of very large cuttings while focusing production efficiencies on techniques to maximize bud and cannabinoid yield. We propose that there’s significant financial benefit from streamlining production during stock plant production and propagation.

In the last issue of Inside Grower, we reported on cannabis stock plant management and cutting production research conducted at Clemson University. This month, we’ll focus on cutting storage prior to propagation. The ability to store harvested cuttings prior to sticking provides growers with flexibility for coordinating cutting harvest dates and sticking dates, which has value for optimizing labor, stock plant space and propagation space.

Why store cuttings?

Following are examples of situations where cutting storage may prove to be valuable:

■ If the number of stock plants of a particular variety (strain) is limited, one can accumulate cuttings harvested over multiple weeks and then stick a larger number of cuttings on a single date. Similarly, if one needs a particularly large number of cuttings for a specific propagation date, cuttings can be harvested over multiple weeks and then stuck simultaneously.

■ If one needs to trash stock plants before the cuttings are needed in propagation.

■ Cutting production can be maximized by harvesting cuttings twice per week, but this system may not match with propagation needs, so the cuttings can be harvested with maximized cutting production in mind and then stored until one reaches the correct number of cuttings for the targeted propagation date.

■ Labor is typically more efficient when performing tasks, like harvesting or sticking cuttings, for an extended time period. Cutting storage allows for harvesting or sticking cuttings in larger batches, since one is not tied to harvesting and sticking on the same date.

■ Scheduling of labor is much more flexible when cuttings do not need to be harvested and stuck on the same date. For example, cuttings can be harvested on Monday, but not stuck in propagation until Friday.

Class project

During the spring semester 2023, students in an undergraduate research course harvested cuttings from four CBD-hemp stock plants: Tiger, Peach, OG and Jack. The cuttings were about 2 in. (5 cm) in length. These cuttings were smaller than the typical industry cuttings, which can be as long as 8 in. Smaller cuttings have several advantages that include higher cutting yield per square foot of stock plant space, higher cutting density in propagation (72-cell trays rather than 35- to 50-cell trays), less labor involved in leaf removal, no leaf trimming, less leaf wilting in propagation and improved rooting. Approximately 50 cuttings were harvested for each variety and the experiment was repeated twice.

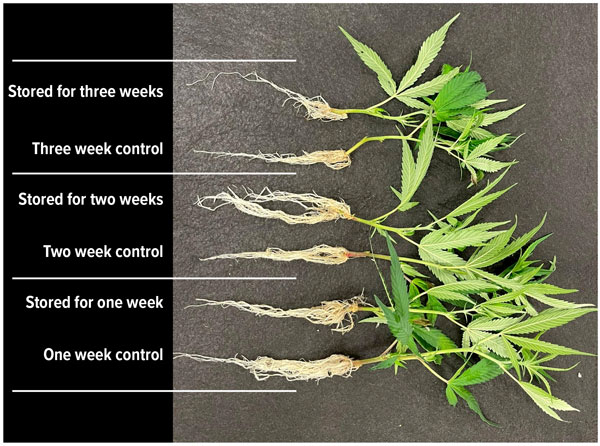

Figure 1. Cannabis cuttings were stored for one, two or three weeks prior to sticking in propagation. A freshly harvested, non-stored, control group was harvested and stuck the same day as the corresponding stored cuttings. The one-week stored cutting and its control cutting were two weeks older than the three-week stored cutting and its control cutting at the time of the photo, thus the one-week cuttings were larger at that time.

The cuttings were placed into Ziploc plastic storage bags, which had 18 small pin-holes poked in the bags with a syringe needle to allow for gas exchange. Unvented storage bags will accumulate gasses produced by the cuttings, such as carbon dioxide and ethylene. Oxygen concentrations inside the bag will drop because oxygen is consumed during respiration. A moistened sheet of paper towel was placed into each bag to humidify the bag and prevent excessive water loss during storage. The paper towel was wetted, then squeezed to remove excess moisture. The goal is for the paper to humidify the bag without the cuttings coming into contact with free moisture, i.e., the cuttings stay dry, but lose water (transpire) at a low rate.

The bags of cuttings were placed inside a refrigerator that provided a 36 to 40F (2 to 4C) environment. This temperature was chosen since maximum postharvest longevity of plant tissues is achieved by low temperatures that don’t cause damage. For example, most cut flowers are stored and shipped at these temperatures. It should be noted that many vegetatively propagated ornamental species are stored and shipped at 50F (10C) because a significant number of those species are chilling sensitive and are thus damaged at colder temperatures (e.g., impatiens, begonias, poinsettias). Zonal geraniums are an exception because they’re usually shipped alone, without other species, and thus are bested handled at 36 to 40F (2 to 4C).

Cuttings for each variety were stored in the refrigerator for 7, 14 or 21 days. After each storage period, cuttings were dipped into a liquid rooting hormone (4,000 ppm K-NAA) and stuck into a peat-based propagation substrate in 72-cell trays. An additional group of freshly harvested cuttings were collected from the stock plants at Day 7, 14 or 21 to serve as a non-stored control group. These cuttings were stuck alongside the stored cuttings to determine if storage slowed rooting compared to non-stored cuttings. After 14 days in propagation, stored and non-stored cuttings were harvested, and rooting was assessed.

What we learned

Three (Peach, OG, Jack) of the four CBD-hemp varieties were stored for up to three weeks without any negative impact on rooting in propagation and no cold damage was exhibited on the cuttings. This demonstrates the potential value of this storage technique. Figure 1 shows cuttings placed in cold storage for one, two or three weeks alongside freshly harvested cuttings at the time the stored cuttings were stuck in propagation. Note that the one-week storage cuttings were two weeks older than the three-week storage cuttings at the time the photo was taken.

However, one of the four varieties (Tiger) displayed chilling-injury symptoms during the first test run, but was fine on the second run. Chilling injury is defined as cold damage that occurs at non-freezing temperatures. The chilling injury symptoms developed after the cuttings were placed into propagation. This is also typical of chilling damage. In contrast, freezing damage resulting from temperatures <32F (0C) will occur during the storage treatment. Tiger cuttings looked green and healthy when removed from cold storage, but with two days in propagation, the cuttings turned necrotic and died (Figure 2). The same phenomenon occurs on many ornamental species, including portulaca, lantana, poinsettia, begonia and impatiens.

However, one of the four varieties (Tiger) displayed chilling-injury symptoms during the first test run, but was fine on the second run. Chilling injury is defined as cold damage that occurs at non-freezing temperatures. The chilling injury symptoms developed after the cuttings were placed into propagation. This is also typical of chilling damage. In contrast, freezing damage resulting from temperatures <32F (0C) will occur during the storage treatment. Tiger cuttings looked green and healthy when removed from cold storage, but with two days in propagation, the cuttings turned necrotic and died (Figure 2). The same phenomenon occurs on many ornamental species, including portulaca, lantana, poinsettia, begonia and impatiens.

Figure 2. Chilling injury of Tiger cannabis cuttings that appeared after one to two days in propagation following cold storage at 36 to 40F (2 to 4C). The other varieties tested showed no damage and Tiger showed damage in just one of two experiments.

It's not clear why Tiger performed well during just one of the two experimental replications. We hypothesize that the refrigerator temperature may have dropped slightly lower and this was enough to damage Tiger. It’s also possible that the cuttings were harvested at different times of the day. We know that some species, such as heliotrope and basil, are more sensitive to chilling temperatures when cuttings are harvested in the morning compared to a mid-day harvest.

The damage that occurred to Tiger also underscores the potential risk involved with cutting storage. Based on these observations, 41F (5C) seems like a safer starting point. Growers should always experiment with a small number of cuttings prior to implementing new techniques such as cutting storage. Also, all varieties should be tested since considerable variation likely exists.

Take-home messages

Three weeks is a relatively long time for cutting storage, so these results are quite promising. We didn’t store cuttings for longer than three weeks, so additional storage time may also be possible. Statistical analysis of root fresh weight indicated no differences between stored and non-stored cuttings, i.e., root formation in propagation wasn’t affected by the storage duration.

We found that several varieties of cannabis have a high tolerance for cold storage for three weeks at 36 to 40F (2 to 4C), while others are sensitive to chilling injury over a short time period and thus cannot be safely stored for any duration at these temperatures. We suggest starting storage trials of your varieties at 41F (5C).

Cuttings can be packaged at relatively high densities. For example, we fit 100, 2-in. cuttings in a 1-gallon storage bag. Thus, a normal-sized refrigerator can potentially store hundreds of cuttings at a time.

These findings may revolutionize the way that both small- and large-scale cannabis producers manage stock plant and propagation spaces, while allowing for more scheduling flexibility for both the labor force and production space. Part 3 in this Inside Grower series will describe techniques to improve propagation success with unrooted cannabis cuttings.

Ashley Canaday, Kathryn Gathers, Dan Greco and Lydia Owens are undergraduate students at Clemson University, and James Faust is a professor.