5/1/2024

Advancing Technology

Jennifer Polanz

As I walked this year’s show floor at the 11th annual Indoor Ag-Con in Las Vegas, I kept seeing products and thinking, “That would be useful for ornamental production … that would be helpful, too … yes, that would work, also.”

From CO2 creation to products focused on water and crop monitoring, the new technology and concepts matched up with the needs for most indoor plant crops, whether that’s leafy greens, tomatoes, strawberries, cannabis, or annuals and potted floral.

This year’s show attracted more than 1,500 attendees from 49 states and U.S. territories, as well as from 31 other countries. On top of that, nearly 150 visitors came from the co-located National Grocers Association event. On the show floor, there was an increase in exhibitors to 207 companies in 287 booths this year. All told, it’s the largest Indoor Ag-Con to date, which prompted a move to a different facility next year to accommodate the growth: March 11-12, 2025 at the Westgate Las Vegas.

Here's a quick look at a few products that caught my eye at the show that can also be applicable in the ornamental world.

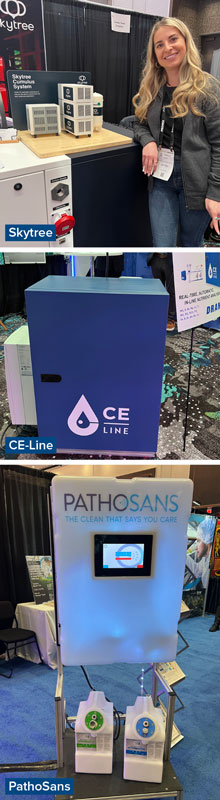

Skytree: Direct Carbon Capture

I wrote about Skytree when they first came on the U.S. scene last year, introducing the proof of concept version of their direct air carbon capture technology initially developed by the European Space Agency. They launched their Cumulus product in January, which is ideal for small-scale growing operations, producing up to 44 lbs. of CO2 daily. The systems are stackable, too, so one control unit can support up to three Cumulus units, and there’s an optional storage tank, as well.

At Indoor Ag-Con, they introduced the brand new Stratus series, which is made for larger indoor production facilities (both vertical farm and greenhouse). Here’s the breakdown:

■ Stratus Hybrid 10: Produces up to 1,100 lbs. of CO2 per day via the most energy-efficient system, using available thermal heat and electricity

■ Stratus Electric 10: Produces up to 1,650 lbs. of CO2 per day, ideal for areas with access to cost-effective green electricity

■ Stratus Electric 20: Produces 2,750 lbs. of CO2 per day as the highest capacity system designed to maximize CO2 capture capacity

Talking to Camille Hanna, business development director, we asked about return on investment, which she said can depend on the comparative cost of CO2 in the grower’s location, but typically is between two and seven years. The company has tools to help interested growers calculate the total cost of ownership, and there are subsidy and incentive programs available to offset costs. Skytree is also looking at additional business models that would be available first on the Cumulus products.

Stratus units will be available likely later this year.

CE-Line (partnering with Dramm in the U.S.): Nutrient Analysis

How beneficial would it be to measure nutrient uptake in your crops in real-time? That’s what CE-Line offers: automated nutrient measurements for macro and micronutrients that are able to integrate into any growing system and result in a nutrient analysis within 45 minutes, said Simon Meijer, CEO of CE-Line.

The company has been trialing the technology in the Netherlands for years and currently has installations in the Netherlands, Norway and Germany. They’d been looking for additional partners and found a U.S. partner in Dramm, in whose booth they were showing the technology. Simon noted that the technology reduces the risk of dosing mistakes, which can be caught early and better addresses the needs of the crop to reduce plant stress. It can be vital to know what nutrients are in the water, too, if the operation is recycling water. And in cases where growers are optimizing lighting and nutrition, they may need very specific dosing to achieve their goals.

The system is adaptable and can be integrated into any environmental control system, Simon said.

BioTherm: Dissolved Oxygen & CO2

BioTherm highlighted several products in their booth that focused on adding dissolved oxygen to irrigation water to improve root health and nutrient uptake in plants. The Oxygen Generation System (OGS) works by capturing oxygen out of the air and sending it through a dissolved gas system to increase the measurable dissolved oxygen in irrigation water. The unit is plug-n-play and connects to BioTherm’s DOS-X Dissolved Oxygen System with flow rates up to 60 gpm (with larger flow available through customization) or to the DGS-m Dissolved Gas System with flow rates up to 50 gpm. Both the DOS-X and DGS systems can be controlled by the DO STAT Dissolved Oxygen Automation Controller with touchscreen interface.

The company also showcased its CO2 enrichment machine that can make CO2 on-site, eliminating the need for tanks. The system pulls CO2 from the boiler’s exhaust gases and redistributes throughout the growing facility.

PathoSans: Sanitation

While the focus for this product at Indoor Ag-Con was on food safety, ornamental growers are still in need of sanitized surfaces. The wall-mounted, on-site compact concentrate generator from PathoSans is new this year and was launched in January. It generates two solutions: a sodium hydroxide cleaner/degreaser and hypochlorous acid disinfectant/sanitizer. It creates both out of salt, water and electricity, and the formulations aren’t irritating to the eyes and skin, which means employees don’t have to use respirators or full PPE when applying it. The formulations can be used in foot baths, floor scrubbers, cleaning trays in propagation rooms and on equipment to kill all standard bacteria. There are multiple options depending on the amount of solution you need.

CEA Advisors/Growtainer: Tissue Culture Lab

CEA Advisors Founder & President Glenn Behrman started his career in the Florida foliage business decades ago, and for the past 15 years he’s been operating CEA Advisors and Growtainers, a global company that creates state-of-the-art production facilities in multiple sizes, including containers.

Though much of Growtainer’s focus is on the food production side, one new concept Glenn told me about at the show is the ability to create a sterile tissue culture lab in 40-ft. or 53-ft. Growtainers. These can be a vehicle for affordable, small volume and easy-to-manage tissue culture propagation. The laboratory equipment, media preparation and sterilization system inside the TC Growtainer are coming from Holland-based Lab Associates, and Glenn has an agreement with Agri-Starts in Florida to provide expertise and support on the growing side.

Neatleaf: Spyder Monitoring System

I met Elmar Mair, CEO and founder of Neatleaf, in the halls at Indoor Ag-Con and he told me about his company’s unique remote crop monitoring system. It’s a similar concept to the cable-suspended camera systems used by TV channels broadcasting NFL and college football games. So picture that, but with a flatter, square unit zooming over the crop, taking temperature, humidity, CO2, leaf temperature, light intensity and other readings (you can see a demo of it in action on the website).

It can remain one height above the plants or it can zoom down closer into the plant canopy, Elmar said. It’s mounted to the greenhouse or vertical farm infrastructure, takes the readings and uploads the data to the cloud for access from anywhere. It uses proprietary AI technology to quantify plant health and forecast yield based on the collected data, as well.

The product was in development for four years and has been deployed in the field for two years now. Elmar added that growers can begin to compare year-over-year data or from crop-to-crop to, for example, track how the crop is doing on Day 22 compared to the previous production cycle. The system is available in the U.S. and Canada currently, with the goal of expanding into Europe. GT